Why does PVC hose become hard and yellow after being used for a long time?

The yellowing of PVC hoses over time is a result of various factors related to the chemical and physical properties of PVC (polyvinyl chloride). Here’s a breakdown of the main reasons for the yellowing:

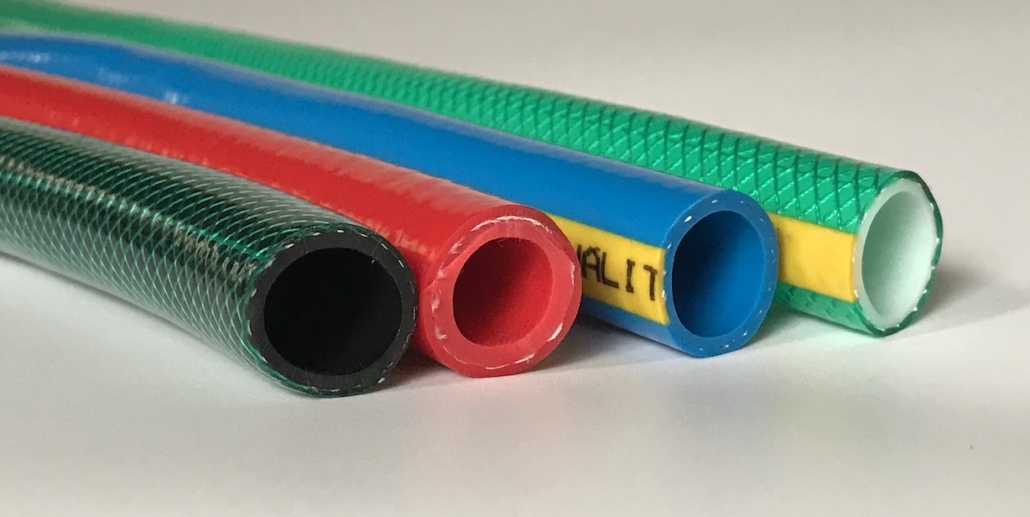

flexible pvc hoses

- Heat and Light Sensitivity: PVC resin is heat-sensitive and has poor light stability. Exposure to heat and light triggers reactions in the PVC molecular structure, leading to the release of hydrogen chloride and the formation of macromolecular free radicals. This oxidation process contributes to the discoloration, starting with yellowing and potentially progressing to blackening.

- Low Molecular Weight Components: PVC resin contains low molecular weight components that reduce the thermal stability of the polymer. Decomposition mechanisms, including free radical and ionic mechanisms, may be accelerated by the presence of impurities such as initiators, catalysts, acids, alkalis, or absorbed water during storage and transportation.

- Impurities in Polymer: If impurities like initiators, catalysts, or other substances are not completely removed during the polymerization process, they can contribute to molecular-ion degradation reactions. The presence of low molecular weight substances can accelerate the thermal decomposition of the resin, leading to yellowing.

- Structural Profiles: Rigid PVC structural profiles, especially those used outdoors, may undergo dehydrochlorination. This process converts components like calcium carbonate into calcium chloride, which disperses in the oxidative degradation product layer. These dispersed components can form potential water absorption sites, contributing to yellowing.

- Stresses during Processing: PVC undergoes various stresses, such as shear stress and tensile stress, during processing steps like stirring and extrusion. These stresses can lead to thermal degradation and contribute to the yellowing of the material.

To mitigate yellowing in PVC hoses, stabilizers, including heat and light stabilizers, can be added during manufacturing. Increasing the amount of stabilizer is one way to address stability issues, especially in PVC/ CPE (chlorinated polyethylene) systems with poor stability. Additionally, careful control of impurities and processing conditions can help minimize the impact of these factors on PVC hose discoloration.

sunhose

sunhose sunhose

sunhose