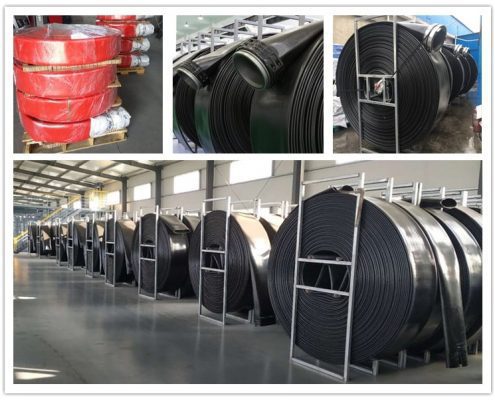

TPU Layflat Hose

TPU Hose, TPU Layflat hose is made from extruded thermoplastic polyester-based polyurethane (TPU) with excellent wear & tear properties. The reinforcement of the TPU Fracking Hose is made from circular woven filament polyester yarn. A TPU layflat hose is a type of hose specifically designed for water transfer and discharge applications. It is constructed using TPU (thermoplastic polyurethane) material, which provides excellent durability, flexibility, and resistance to abrasion and chemicals. TPU layflat hoses are commonly used in industries such as agriculture, construction, mining, and irrigation.

- Tube: Thermoplastic polyether-based polyurethane (TPU).

- Reinforcement: Circular woven filament polyester yarn.

- Cover: Thermoplastic polyurethane (TPU).

- Application: For fire-fighting, shipping, petroleum, Chemical industry, Agriculture, Mining. Transfer of chemicals, oil & fuel, abrasive substances, potable water, or transfer over the highly abrasive ground.

- Temp. Range. : – 46 ̊C to +80 ̊C (-50.8°F to 176°F)

Specification of TPU Layflat Discharge Hose

TPU layflat hoses are known for their lightweight nature and easy handling. They are designed to be flat when not in use, allowing for compact storage and transportation. When water is pumped through the hose, it expands and becomes rigid, enabling efficient water transfer over long distances. One of the key advantages of TPU layflat hoses is their high tensile strength, allowing them to withstand high-pressure applications. They are reinforced with synthetic fibers or polyester yarns, providing additional strength and preventing the hose from bursting or collapsing under pressure. TPU hoses can handle both low and high-pressure water transfer tasks. TPU layflat hoses offer excellent resistance to punctures, abrasion, and UV rays, making them suitable for use in demanding outdoor environments. They have a smooth inner surface that minimizes friction and ensures efficient water flow. The hoses are also resistant to mildew and mold, allowing for long-term use in wet conditions.

| Part No. | Size | I.D. | Working Pressure | Burst Pressure | Thickness | Weight | Length | ||

|---|---|---|---|---|---|---|---|---|---|

| # | Inch | mm | Bar | PSI | Bar | PSI | mm | kg/m | m/coil |

| SHPU0025 | 1″ | 25+1.5 | 10/16 | 150/240 | 30/48 | 450/720 | 2.5-3.0 | 0.20-0.30 | 20-200 |

| SHPU0051 | 2″ | 51+1.5 | 10/16 | 150/240 | 30/48 | 450/720 | 2.5-3.0 | 0.29-0.55 | 20-200 |

| SHPU0063 | 2-1/2″ | 63.5+1.5 | 10/16 | 150/240 | 30/48 | 450/720 | 2.5-3.0 | 0.45-0.75 | 20-200 |

| SHPU0076 | 3″ | 76+2.0 | 10/16 | 150/240 | 30/48 | 450/720 | 2.8-3.5 | 0.60-1.00 | 20-200 |

| SHPU0102 | 4″ | 102+2.0 | 16/20/28 | 240/300/420 | 48/60/84 | 720/900/1260 | 4.5-5.0 | 1.00-1.80 | 20-200 |

| SHPU0127 | 5″ | 127+2.0 | 16 | 240 | 48 | 720 | 4.5-5.0 | 1.20-2.00 | 20-200 |

| SHPU0152 | 6″ | 152+2.0 | 16/28/42 | 240/420/630 | 48/84/84 | 720/1260/1260 | 3.9-5.5 | 2.0-4.0 | 20-200 |

| SHPU0203 | 8″ | 203+2.0 | 16/20 | 240/300 | 48/60 | 720/900 | 3.8-4.5 | 3.0-4.2 | 20-200 |

| SHPU0254 | 10″ | 254+3.0 | 13/16 | 195/240 | 39/48 | 585/720 | 4.6-5.5 | 4.2-6.0 | 20-200 |

| SHPU0305 | 12″ | 305+3.0 | 10/13 | 150/195 | 30/39 | 450/585 | 4.4-5.5 | 4.4-6.2 | 20-200 |

| SHPU0356 | 14″ | 356+4.0 | 5 | 75 | 15 | 225 | 3.5-4.0 | 3.5-4.3 | 20-200 |