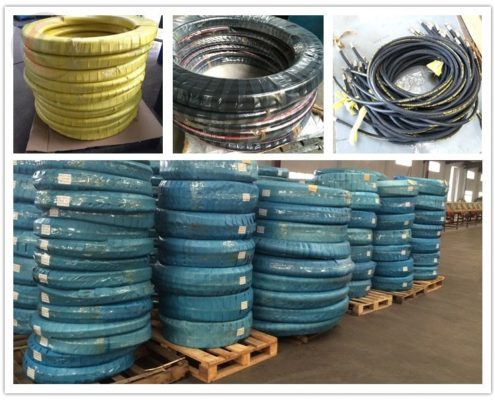

Hydraulic Hose SAE 100 R2AT/2SN (Wrap & Smooth Cover)

SAE 100 R2AT / EN 853 2SN Hydraulic Hose High-pressure hydraulic oil lines used in construction, machine tool, and agricultural applications using petroleum or water-based hydraulic fluids.Mangueras hidraulicas.

The SAE 100 R2AT / EN 853 2SN Hydraulic Hose is a specific type of hydraulic hose that meets the requirements of both SAE 100 R2AT and EN 853 2SN standards. These standards define the hose’s construction, performance, and compatibility with hydraulic fluids, ensuring its reliability and performance in hydraulic systems.

The “SAE 100 R2AT” designation refers to the Society of Automotive Engineers (SAE) standard for hydraulic hoses. It specifies the hose’s construction, including its inner tube, reinforcement layers, and outer cover. The hose is designed to handle high-pressure hydraulic applications and transmit hydraulic power efficiently.

Similarly, the “EN 853 2SN” designation refers to the European standard for hydraulic hoses. It ensures the hose’s compliance with specific requirements for pressure rating, burst pressure, flexibility, and compatibility with hydraulic fluids.

- Tube: Oil resistant Nitrile (BTR) tube.

- Reinforcement: Two braids of high-tensile steel wire.

- Cover: Abrasion and weather resistant synthetic rubber.

- Application: In an abrasive or severe outdoor environment such as offshore, forestry, construction, and mining.

- Temp. Range. :– 40 ̊C to + 125 ̊C (40°F to 257°F)

Specification of Hydraulic Hose SAE 100 R2AT/2SN

SAE 100 R2AT Double wire braid hydraulic hose Medium pressure service with high temperature petroleum-based hydraulic fluids, hot oil, grease, lubricants and crude oils, air, and water. For air or gas applications above 250 PSI (1.7 Mpa), the cover should be pin-pricked. The SAE 100 R2AT / EN 853 2SN hydraulic hose is commonly used in a wide range of hydraulic systems, including industrial machinery, construction equipment, agricultural machinery, and more. It can handle high-pressure hydraulic fluids and transmit hydraulic power between components such as pumps, valves, cylinders, and motors.

| Part No. | SIZE | SAE | I.D | W.D | O.D | W.P | P.P | B.P | min B.R | W.T | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | AT | ||||||||||||||||||

| # | mm | inch | Dash | Min | Max | Min | Max | Min | Max | Max | Mpa | Psi | Mpa | Psi | Mpa | Psi | inch | mm | Kg/m |

| SHHR205 | 5 | 3/16″ | -3 | 4.6 | 5.4 | 10.6 | 11.7 | 15.1 | 16.7 | 14.1 | 35 | 5075 | 70 | 10150 | 140 | 20300 | 3.54 | 90 | 0.32 |

| SHHR206 | 6.3 | 1/4″ | -4 | 6.2 | 7 | 12.1 | 13.3 | 16.7 | 18.3 | 15.7 | 35 | 5075 | 70 | 10150 | 140 | 20300 | 3.94 | 100 | 0.36 |

| SHHR208 | 8 | 5/16″ | -5 | 7.7 | 8.5 | 13.7 | 14.9 | 18.3 | 19.8 | 17.3 | 29.7 | 4310 | 59.5 | 8630 | 119 | 17255 | 4.53 | 115 | 0.45 |

| SHHR210 | 10 | 3/8″ | -6 | 9.3 | 10.1 | 16.1 | 17.3 | 20.6 | 22.2 | 19.7 | 28 | 4060 | 56 | 8120 | 112 | 16240 | 4.92 | 125 | 0.54 |

| SHHR213 | 13 | 1/2″ | -8 | 12.3 | 13.5 | 19 | 20.6 | 23.8 | 25.4 | 23.1 | 24.5 | 3550 | 49 | 7110 | 98 | 14210 | 7.09 | 180 | 0.68 |

| SHHR216 | 16 | 5/8″ | -10 | 15.5 | 16.7 | 22.2 | 23.8 | 27 | 28.6 | 26.3 | 19.2 | 2780 | 38.5 | 5580 | 77 | 11165 | 8.07 | 205 | 0.80 |

| SHHR219 | 19 | 3/4″ | -12 | 18.6 | 19.8 | 26.2 | 27.8 | 31 | 32.5 | 30.2 | 15.7 | 2280 | 31.5 | 4570 | 63 | 9135 | 9.45 | 240 | 0.94 |

| SHHR225 | 25 | 1″ | -16 | 25 | 26.4 | 34.1 | 35.7 | 38.5 | 40.9 | 38.9 | 14 | 2030 | 28 | 4060 | 56 | 8120 | 11.81 | 300 | 1.35 |

| SHHR232 | 32 | 1-1/4″ | -20 | 31.4 | 33 | 43.2 | 45.6 | 49.2 | 52.4 | 49.6 | 11.3 | 1640 | 22.7 | 3290 | 45.5 | 6600 | 16.54 | 420 | 2.15 |

| SHHR238 | 38 | 1-1/2″ | -24 | 37.7 | 39.3 | 49.6 | 52 | 55.6 | 58.7 | 56 | 8.7 | 1260 | 17.5 | 2540 | 35 | 5075 | 19.69 | 500 | 2.65 |

| SHHR251 | 51 | 2″ | -32 | 50.4 | 52 | 62.3 | 64.7 | 68.3 | 71.4 | 68.6 | 7.8 | 1130 | 15.7 | 2280 | 31.5 | 4570 | 24.80 | 630 | 3.42 |