How to choose camlock couplings?

A Camlock fitting also called a cam and groove coupling is used to connect two hoses and or pipes together in a variety of industries so that a commodity (medium) from one can be transferred to the other. They are simple to connect and disconnect, requiring no tools to connect and disconnect the two halves of the couplings and they replace the traditional time-consuming methods of some other types of hose or pipe connections. This, together with their cost effectiveness makes them the most popular coupling in the world.

| Material | Characteristic | Advantage | Disadvantage | Application |

|---|---|---|---|---|

| Aluminum Alloy | low density, high intensity good plasticity electrical and thermal conductivity anti-corrosion | low cost | relative to stainless steel material, corrosion resistance is poor easy mildew and oxidation | fresh water oil-water mixtures |

| Stainless Steel | anti-corrosion formability compatibility durability | clean inner wall temperature resistance high strength | high cost | acid, alkali and highly corrosive areas |

| Polypropylene | low density anti-acid, anti-alkali, anti-organic solution chemical stability anti-aging | good leakproofness light weight low price easy operation | low strength easy to deform | acid, alkali environment chemical industry liquids transmission agriculture irrigation |

| Nylon | heat resistance Higher density than PP resistance to changing humidity dimensional stability | good leakproofness light weight low price easy operation | low strength easy to deform | acid, alkali environment chemical industry liquids transmission agriculture irrigation |

| Brass | electrical conductivity seawater resistant | easy to assemble | high cost | salty water and any media except for acid and alkali shipbuilding industry deep well operations |

Aluminum Alloy Camlock Coupling

- Introduction

- According to the processing method, aluminum alloy can be divided into two categories: deformation aluminum alloy and casting aluminum alloy. Aluminum alloy camlock coupling generally adopts the casting processing method.

- According to the chemical composition, casting aluminum alloy can be divided into aluminum-silicon alloy, aluminum copper alloy, aluminum magnesium alloy, Al-Zn alloy, and rare earth aluminum alloy.

- Deformation aluminum alloy is mainly used in the production of aviation equipment and windows or doors of buildings. It can be divided into non-heat-treatable reinforced aluminum alloy and heat-treatable reinforced aluminum alloy. Some aluminum alloys are treated by heat treatment to obtain good mechanical properties, physical properties, and corrosion resistance properties.

- Characteristic

- Low density, high intensity.

- It can be processed into various profiles with good plasticity.

- Excellent electrical conductivity, thermal conductivity, and corrosion resistance.

- Advantage: low cost.

- Disadvantage: relative to stainless steel material, corrosion resistance is poor, easy mildew and oxidation.

- Application: aluminum alloy is mainly used in low-demand fluids such as fresh water and oil-water mixture.

Stainless Steel Camlock Coupling

- Introduction

- Stainless steel is not easy to rust. In fact, some stainless steel is not only rustproof but also rotproof, the reason is the formation of oxidation film which riches in chromium.

- The material of stainless steel Camlock coupling can be divided into three types: SS 304, SS 316, and SS 316L. SS 316L material is the best and its price of it is the highest.

- The brightness of stainless steel material is close to mirroring, and the touch of it is hard and cold. Stainless steel belongs to the avant-garde decoration material, and it is in line with the aesthetic of the metal age.

- Characteristic

- Excellent corrosion resistance.

- Formability.

- Compatibility.

- Strong enough in a wide temperature range.

- Advantage

- The inner wall of the stainless steel Camlock coupling is clean, this helps to avoid impurities condensation, bacteria breeding, peculiar smell production, and media pollution.

- The intensity of the stainless steel Camlock coupling is excellent. Generally speaking, intensity lacking is the common reason for Camlock coupling leakage caused by external forces.

- Stainless steel Camlock coupling has great temperature resistance, it can work safely for a long time between -30 °C to 230 °C. In addition, stainless steel has stable performance, which is not easy to corrode.

- Disadvantage: high cost.

- Application

- It can be used in highly corrosive areas and acid, and alkali media.

- It also can be used in many industries, such as heavy industry, light industry, daily necessities industry, construction, and decoration industry.

- Applicable environment

- Pressure: Camlock coupling withstands the pressure of almost 16 kilograms of objects, but when it connects with the tubes, it can withstand the pressure of hundreds of kilograms of objects.

- Temperature: -30 °C to +230 °C.

- Media: gasoline, mazut, kerosene, hydraulic oil, fuel oil, refrigerating machine oil, water, brine, acidic and alkaline liquids, etc.

- Connection method: internal thread, external thread, hose, flange, butt welding, socket weld, wrench type.

- Sealing material: NBR, Viton, EPDM. The most popular material is NBR, and the most expensive is Viton.

- Thread type: NPT, BSPT, BSP.

Plastic (PP & Nylon) Camlock Coupling

- Introduction: plastic Camlock coupling can be divided into PP (polypropylene) material and nylon material. Plastic Camlock coupling has a beautiful appearance. And it uses high-quality NBR to seal, so it is safe and reliable. In addition, if the specification is the same, any B, C, D, or DC type can combine with any of E, F, A, or DP types.

- Advantage

- Low price, lightweight.

- Simple structure and easy operation.

- With a good seal.

- Disadvantage: low intensity, easy to deform.

- Application

- It can be used for agriculture irrigation and liquid transmission in a variety of media, such as water, oil, gas, and some corrosive liquids.

- It also can be used in the chemical industry.

- PP characteristic

- Low density.

- Anti-acid, anti-alkali, and anti-organic solutions.

- Excellent electrical insulation and chemical stability.

- High-temperature resistance, anti-aging.

- Low hot-melt rate, smooth surface.

- Nylon characteristic

- The density is higher than PP.

- High heat resistance.

- Excellent combination of rigidity and toughness.

- Resistance to changing humidity.

- Excellent dimensional stability.

- Smooth surface, high surface quality.

Brass Camlock Coupling

- Characteristic

- Good electrical conductivity.

- Seawater resistant.

- Advantage: easy to assemble.

- Disadvantage: high cost.

- Application

- Except for acid and alkali, they can be used in salty water and any media.

- It also can be used in deep good operations and the shipbuilding industry.

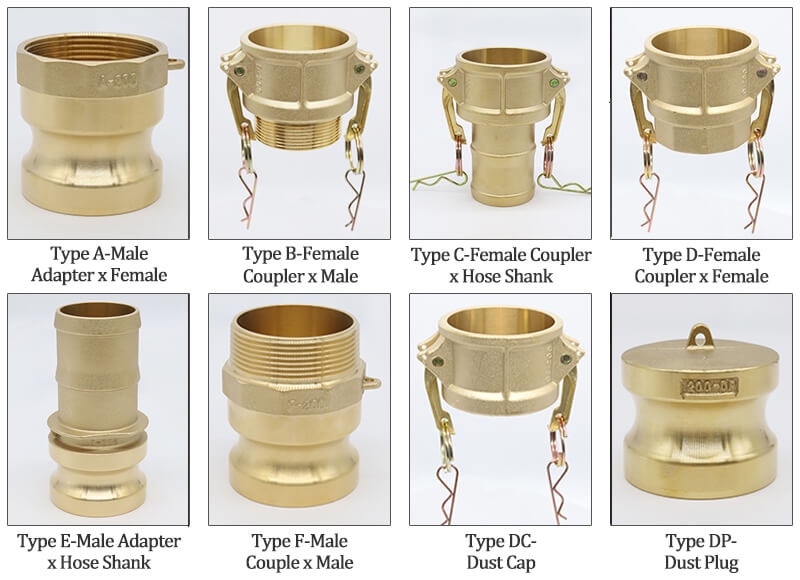

Camlock coupling types

Camlock couplings are identified by their type designations, which are listed below while the image shows a visual reference for the various coupling types.

- Type A: Plug with Female Thread

- Type B: Coupler with Male Thread

- Type C: Coupler with Hose Tail

- Type D: Coupler with Female Thread

- Type E: Plug with Hose Tail

- Type F: Plug with Male Thread

- Type DC: Dust Cap for plugs

- Type DP: Dust Plug for Couplers

How Does the Camlock Coupling Work?

The cam and groove assembly consists of a male groove adapter and a female coupler.

To connect and disconnect:

- Extend the handles on the coupler outwards and place the correct size male adapter into the female coupler

- Close both handles at the same time until the two halves are firmly fixed together

- Closing both handles at the same time ensures that the grooved adapter is pulled down evenly onto the seal making a leakproof assembly for the safe transfer of liquids

- Reverse the process to disconnect the fitting making sure before doing so that the hose assembly has been de-pressurized.

sunhose

sunhose sunhose

sunhose